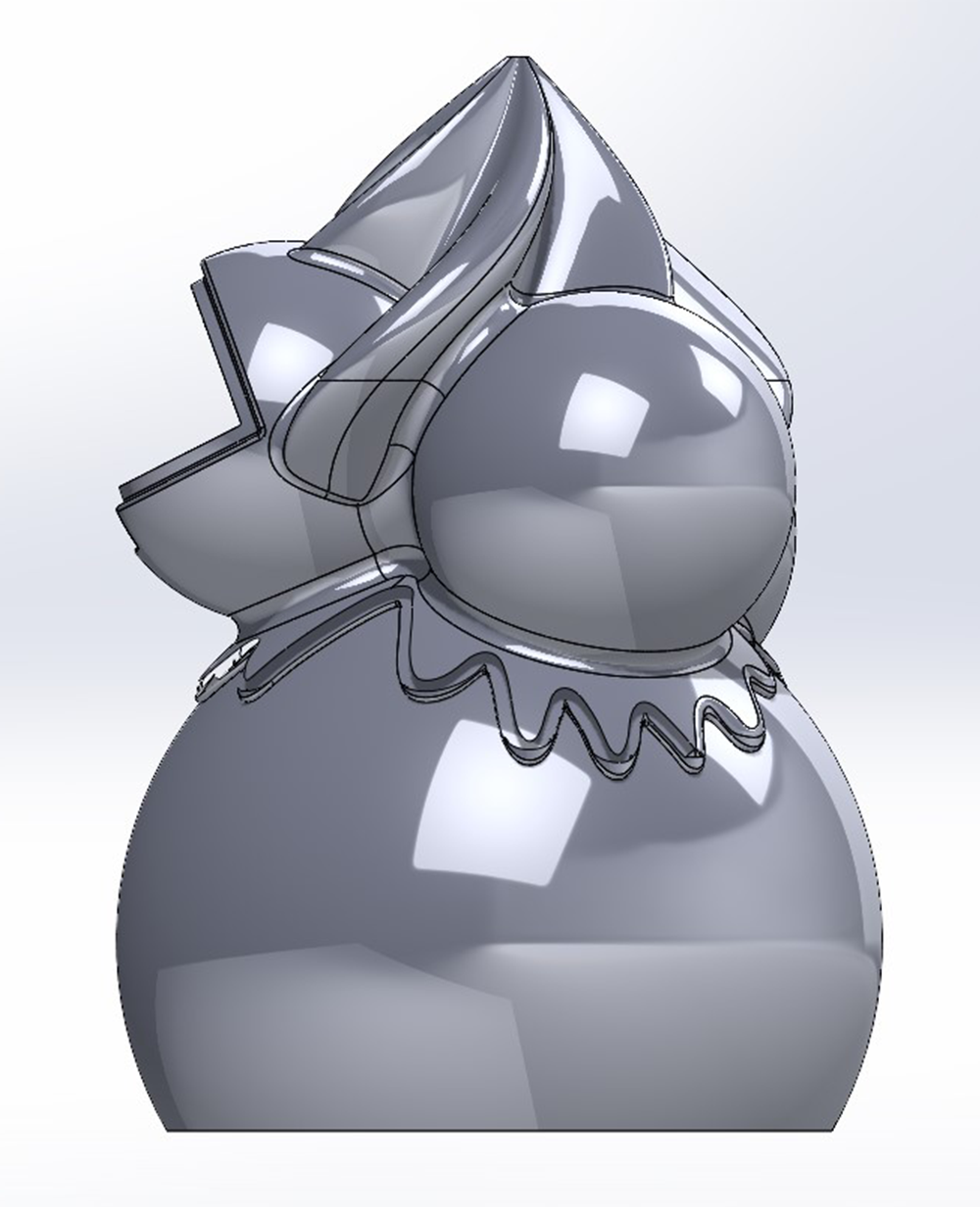

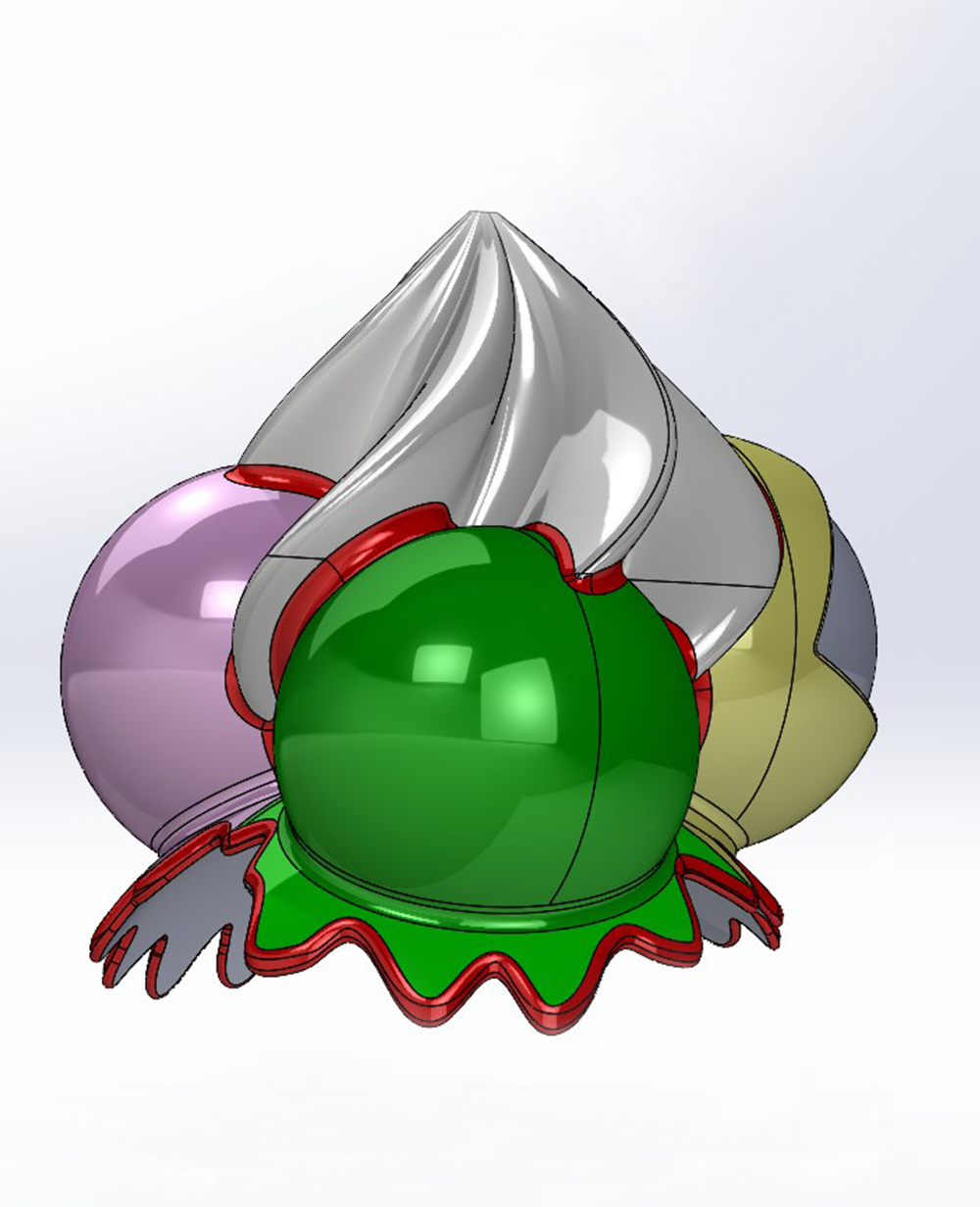

Creation of the model according to the customer’s directives

MODEL DESIGN BASED ON MATHEMATICAL DATA PROVIDED BY THE CUSTOMER OR FROM SCRATCH, BASED ON THE CUSTOMER’S PROJECT

The Technical Office of GR Composites S.r.l. uses modern software and cutting-edge programs for the 3D processing of projects and for the subsequent planning of the various modeling phases at the five-axis milling center within the company.

MODEL PROCESSING INSIDE

OF THE 5-AXIS WORKING CENTER

We have a 5-axis machining center for milling three-dimensional models.

The working area available to us is 5000 millimeters in X (length), 2000 in Y (width) and 1200 in Z (height).

FINISHING OF THE MODELS OBTAINED WITH ROBOTIC MILLING

CREATION OF MOLDS AND ANY COUNTER MOLDS

PERIODIC MAINTENANCE OF MOLDS AND COUNTERMOLDS

The model obtained is taken over by the Modeling Department which will take care of its manual finishing. This processing phase consists in correcting any small inaccuracies due to the gluing and porosity of the materials used.